Hongtai refractory factory price high density 94-97% acid proof silica fire brick for hot blast stove

Hongtai refractory factory price high density 94-97% acid proof silica fire brick for hot blast stove

Silica refractory brick for hot blast stove is used to build siliceous refractory products with tridymite as the main crystal phase in the high-temperature part of blast furnace hot blast stove. The hot air temperature of the blast furnace increased from 500-650°C in the 1940s to 1000°C in the 1970s, and the hot air temperature of the large blast furnaces in the 1980s has increased to 1350°C. Due to the increase in air temperature, the clay bricks or high alumina bricks used in the high temperature parts of the previous hot blast stoves are gradually replaced by silica bricks and low creep high alumina bricks.

Hot blast stove silica brick has the following characteristics:

(1) Under long-term high temperature and load conditions, the volume is stable and the high temperature creep rate is low, and one or even two blast furnace campaigns can be used continuously.

(2) Good thermal shock resistance above 600℃. Adapt to the variability of the temperature of the hot blast stove to keep bricks and masonry intact

(3) The chemical resistance is better than clay bricks and general high alumina bricks. The corrosion of the alkaline substances in the gas and smoke on the silica bricks is limited to the formation of a layer of glass on the surface, and no peeling occurs.

(4) The thermal conductivity of silica bricks is larger than that of clay bricks and high alumina bricks, which is conducive to storing and releasing heat in a shorter time.

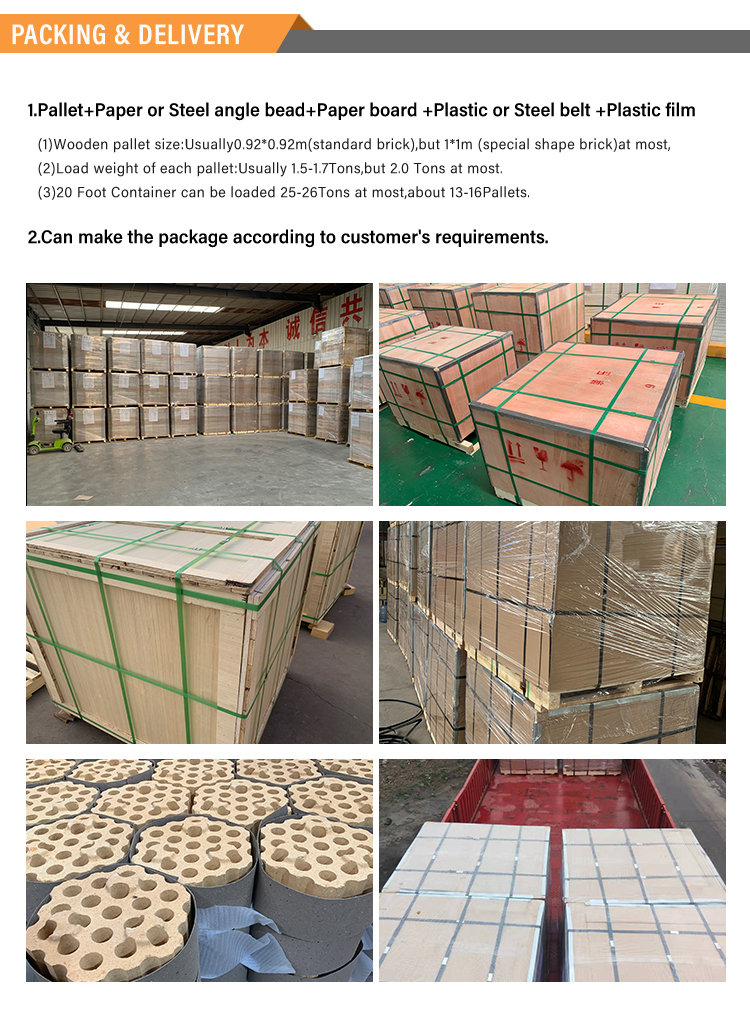

The shape of the product should be regular and the size deviation should be small. The hole diameter of the checker bricks should be ±1mm. The bricks used in other parts should not exceed ±1%. If the joints of the upper pipes of the external combustion hot blast stove are made of composite bricks, they must be cut before masonry. Grind and pre-assemble. The width of the surface crack is not more than 0.5mm, and there should be a length limit side. Cracks with a width of less than 0.1mm will not affect the use, and there should be no cracks caused by improper cooling.

The quartzite containing 98% SiO2 is crushed into particles and fine powder less than 2.5mm. Stored separately according to particle size, using appropriate

When grading. Add mineralizers and binders, knead in a wet mill, and then shape them on a brick press. After the bricks are dried, they are fired at a temperature of 1308-1450°C. Products after cooling should be selected one by one.

Henan Hongtai Kiln Refractory Co., Ltd.-Xinmi refractories, clay bricks, insulation bricks, castables, high alumina bricks, fused cast AZS bricks, mullite bricks, phosphate bricks, magnesia alumina spinel bricks, kiln one-stop service manufacturer. Established in 2002, it is an established manufacturer of professional stereotypes, unshaped refractories, and furnaces with one-stop service, and a designated service provider for top 500 companies.

Application of silica refractory brick for hot blast stove:

Silica Brick should be stored in a waterproof warehouse, and it can still be used after being dried slowly at a temperature below 100°C after being wet. After freezing, the strength of hydrated silica bricks will be affected, and they need to be re-inspected. Furnace construction should leave expansion joints according to the thermal expansion rate provided by the manufacturer. The temperature-time heating curve of the oven should be formulated reasonably, especially in the stage where the expansion is more intense before 600℃, it should be strictly controlled.

Technical Data of silica refractory brick for hot blast stove:

|

Item |

BG-94 |

BG-95 |

BG-96A |

BG-96B |

|

|

Chemical composition |

SiO2 |

≥94 |

≥95 |

≥96 |

≥96 |

|

Fe2O3 |

≤1.5 |

≤1.5 |

≤0.8 |

≤0.7 |

|

|

Al2O3+TiO2+R2O |

|

≤1.0 |

≤0.5 |

≤0.7 |

|

|

Refractoriness °C |

1710 |

1710 |

1710 |

1710 |

|

|

Apparent Porosity% |

≤22 |

≤21 |

≤21 |

≤21 |

|

|

Bulk Density g/cm3 |

≥1.8 |

≥1.8 |

≥1.8 |

≥1.8 |

|

|

True Density,g/cm3 |

≤2.38 |

≤2.38 |

≤2.34 |

≤2.34 |

|

|

Cold Crushing Strength Mpa |

≥24.5 |

≥29.4 |

≥35 |

≥35 |

|

|

0.2Mpa Refractoriness Under Load T0.6 °C |

≥1630 |

≥1650 |

≥1680 |

≥1680 |

|

|

Permanent Linear Change On Reheating (%)1500°CX2h |

0~+0.3 |

0~+0.3 |

0~+0.3 |

0~+0.3 |

|

|

20-1000°C Thermal Expansich10-6/°C |

1.25 |

1.25 |

1.25 |

1.25 |

|

|

Thermal Conductivity (W/MK) 1000°C |

1.74 |

1.74 |

1.44 |

1.44 |

|

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier