High quality slag resistant Magnesia Dolomite Brick for cement plant transition zone

High quality slag resistant

Magnesia Dolomite Brick for cement plant transition zone

Introduction of Magnesia Dolomite Brick

High-purity Magnesia Dolomite Brick fired at ultra-high temperature

Magnesia Dolomite Brick is an alkaline refractory material with CaO and MgO as the main components. Generally, it refers to a MgO-CaO system refractory material containing 10%-40% CaO and 50%-85% MgO. Magnesia Dolomite Brick are widely used in alkaline converters. China's converter lining mainly uses tar-combined dolomite bricks and tar-combined Magnesia Dolomite Brick. Some factories use light-burned oil immersion and fired oil-immersed Magnesia Dolomite Brick in vulnerable parts. In Western Europe and Japan, converters mainly use tar-combined heat-treated and fired oil-immersed dolomite bricks and Magnesia Dolomite Brick. In addition, fired oil-impregnated Magnesia Dolomite Brick are also used as the lining of some refining furnaces outside the furnace.

The high-purity Magnesia Dolomite Brick fired at ultra-high temperature mainly include: synthetic magnesia dolomite sand and high-purity magnesia as raw materials, anhydrous binder, high-pressure molding, ultra-high temperature (1700 ℃ or higher) firing and product adoption Waterproof measures.

The performance characteristics of ultra-high temperature fired high-purity Magnesia Dolomite Brick:

(1) Magnesia Dolomite Brick has Good high temperature resistance.

The melting points of the main components MgO and CaO are as high as 2800℃ and 2600℃ respectively, and the eutectic temperature of the two is also 2370℃. The microstructure is determined by MgO/CaO, but the direct combination of the two is the main feature of the microstructure. Since the total amount of impurities (SiO2, Fe2O3 and Al2O3) is generally not more than 3%, sometimes not more than 2.5%, the starting temperature of load softening exceeds 1700°C.

(2) Magnesia Dolomite Brick has High thermodynamic stability.

Since the free energy of CaO is the most negative (most stable), Magnesia Dolomite Brick are more stable than magnesia chrome bricks under vacuum, and the possibility of re-supplying molten steel with oxygen is the smallest. As long as there is ~20% CaO in the brick, the relative volatilization of MgO will be significantly reduced (because a small amount of CaO is solid-melted in MgO and MgO is preferentially volatilized, a CaO-rich layer is formed in the MgO-CaO material). The thermodynamic stability of the fired magnesia dolomite brick determines its applicability in the use of refined steel tanks outside the furnace working under high temperature vacuum.

(3) Magnesia Dolomite Brick has The ability to purify molten steel.

Clean steel requires that the inner lining of the steel tank does not pollute the molten steel and preferably can purify the molten steel. The fired magnesia dolomite brick containing 20% free CaO has obvious desulfurization effect, and it can be used as the lining of desulfurization steel tank;

(4) Magnesia Dolomite Brick has Excellent slag resistance.

Magnesia Dolomite Brick containing free CaO are more adaptable to molten slag: it has strong corrosion resistance to high alkalinity (high CaO/SiO2&) slag; for low alkalinity slag, due to the high activity of free CaO in the brick It will preferentially react with the SiO2 in the slag to form high melting point and high viscosity 2CaO•SiO2 and 3CaO•SiO2 protective layers, which are attached to the working surface of the brick to block the pores and prevent further erosion of the lining brick by the slag.

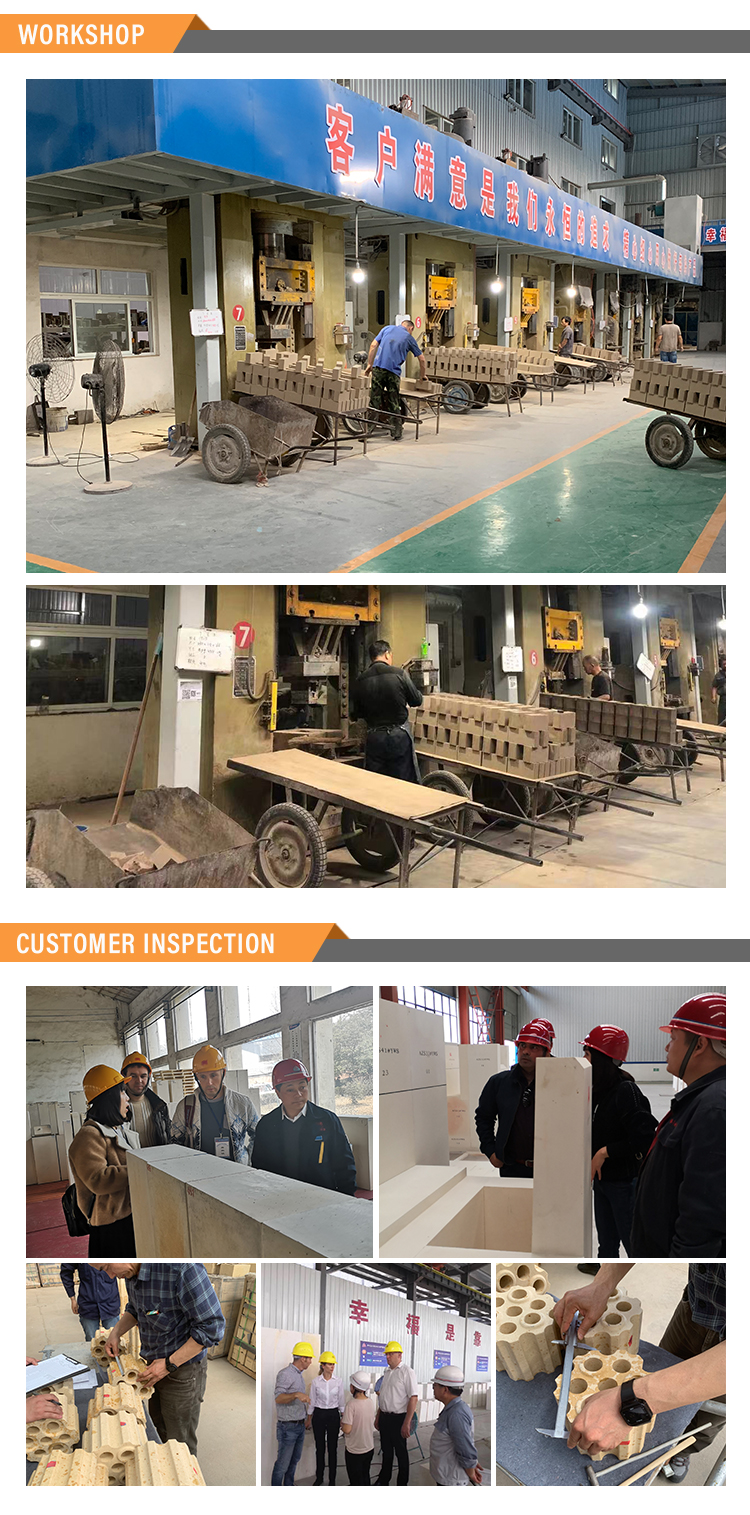

The production process of Magnesia Dolomite Brick

Technical Data sheet of Magnesia Dolomite Brick

| Item | Magnesium Dolomite Brick | |||||

| Brand | QMG-15 | QMG-20 | QMG-25 | QMG-30 | QMG-40 | QMG-50 |

| MgO % ≥ | 80.3 | 76.3 | 70.3 | 66.3 | 56.3 | 43.3 |

| CaO % ≥ | 17 | 21 | 27 | 31 | 41 | 54 |

| Al2O3 % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Fe2O3 % ≤ | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| SiO2 % ≤ | 1.3 | 1.3 | 1.3 | 1.3 | 1.2 | 1.3 |

| Bulk Density (g/cm3) ≥ | 3.03 | 3.03 | 3.03 | 3.03 | 3 | 2.93 |

| Apparent Porosity % ≤ | 13 | 12 | 12 | 13 | 13 | 12 |

| Cold Crushing Strength (Mpa) ≥ | 80 | 90 | 80 | 80 | 80 | 70 |

| 0.2Mpa R.U.L. (℃) ≥ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

Application of Magnesia Dolomite Brick

In recent years, the use of Magnesia Dolomite Brick has become more and more widespread, especially in the AOD furnace has achieved better results. The world's stainless steel production is on the rise, and more than 75% of stainless steel production uses the AOD method. At present, the refractory materials used in AOD furnaces are mainly dolomite bricks, Magnesia Dolomite Brick and magnesia chrome bricks. Magnesia chrome bricks are used in the United States, fired dolomite bricks are used in Germany, unfired dolomite bricks are mainly used in Italy, Magnesia Dolomite Brick are used in Japan, and pure dolomite bricks are used in Europe. The use effect of Magnesia Dolomite Brick is better than that of magnesia-chrome bricks. From the perspective of development trend, magnesia-calcium bricks will replace magnesia-chrome bricks.

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier