Factory Price Henan high temperature resistance Low-Porosity fire clay brick for blast furnace with high density

Henan high temperature resistance

Low-Porosity fire clay brick for blast furnace with high density

Introduction of Low Porosity Clay Brick

Low-porosity clay bricks are mainly made of high-alumina bauxite and scorched gemstones, which are prepared by adding sillimanite and andalusite in proportions, adding binders and adhesives, kneading, forming, drying, and then kiln firing. Low-porosity clay products.

Characteristics of low-porosity clay bricks

1. The apparent porosity is low and the compactness is strong.

2. Good penetration resistance and erosion resistance.

3. High temperature strength and long service life.

Application of Low Porosity Clay Brick

Mainly used in the regenerator of glass kilns, it can also be used in blast furnaces and hot blast furnaces in the iron and steel industry; cement kilns in the building materials industry; chemical kilns in the chemical industry as kiln linings. Features of low-porosity clay bricks: high strength, high refractoriness, compact structure, low pores, good thermal shock stability, and anti-stripping.

Technical Data Sheet of Low-Porosity fire clay brick

| Items | Technical Data | |||

| Chinese code name | Fire Clay Brick | Low-Porosity clay brick | ||

| Grade | N-1 | N-2a | N-15 | N-12 |

| Al2O3 min% | 42 | 40 | 42 | 45 |

| Refractoriness(℃) min | 1750 | 1730 | 1750 | 1750 |

| Apparent Porosity % max | 22 | 24 | 15 | 12 |

| Bulk Density g/cm3 | 2.15 | 2.1 | 2.3 | 2.37 |

| Refractoriness under Load(℃) min | 1400 | 1320 | 1470 | 1500 |

| Permanent linear change % | 1400℃×2h | 1350℃×3h | 1400℃×2h | 1400℃×2h |

| +0.1~-0.4 | +0.2~-0.5 | +0~-0.2 | +0.5~-0.1 | |

Application of Low-Porosity fire clay brick

high alumina brick are mainly used to build blast furnaces, hot blast stoves, electric furnace tops, blast furnaces, reverberatory furnaces, rotary kiln linings, cement rotary kiln transition zones, preheaters and other thermal equipment requiring heat shock resistance; in addition, high alumina brick are also widely used as open hearth regenerative checker bricks, plugs for pouring systems, nozzle bricks, etc.

Other high alumina brick classification

ClassⅠ: Al2O3 content>75%

ClassⅡ: Al2O3 content is 60~75%

ClassⅢ: Al2O3 content is 48-60%.

If Al2O3 content is higher than 80%, it is called super high alumina brick

If Al2O3 content is higher than 90%, it is called corundum brick.

2. Classification of high alumina brick by firing process

It can be divided into fired high alumina brick and unfired high alumina brick. The firing temperature of the first and second grade high alumina brick is 1500℃-1600℃ and 1450℃-1500℃ respectively, while the third grade is lower. High-alumina non-sintered bricks mainly refer to phosphate high-alumina.

3. Classification of high alumina brick by mineral composition

It can be divided into five types: low mullite, mullite, mullite, corundum, corundum and corundum;

4. Classification of high alumina brick according to different shapes

It can be divided into standard high alumina brick, special-shaped high alumina brick and special high alumina brick;

5. Classification of high alumina brick according to their properties

It can be divided into ordinary high alumina brick and special high alumina brick (thermal shock resistance, low creep, anti-stripping high alumina brick;

6. Classification of high alumina brick by use

It can be divided into high-aluminum and high-alumina bricks, hot-blast stove high-alumina bricks, steel-making electric furnace top high-alumina bricks, Shenggang barrel high-alumina bricks, and inner cast high-alumina bricks.

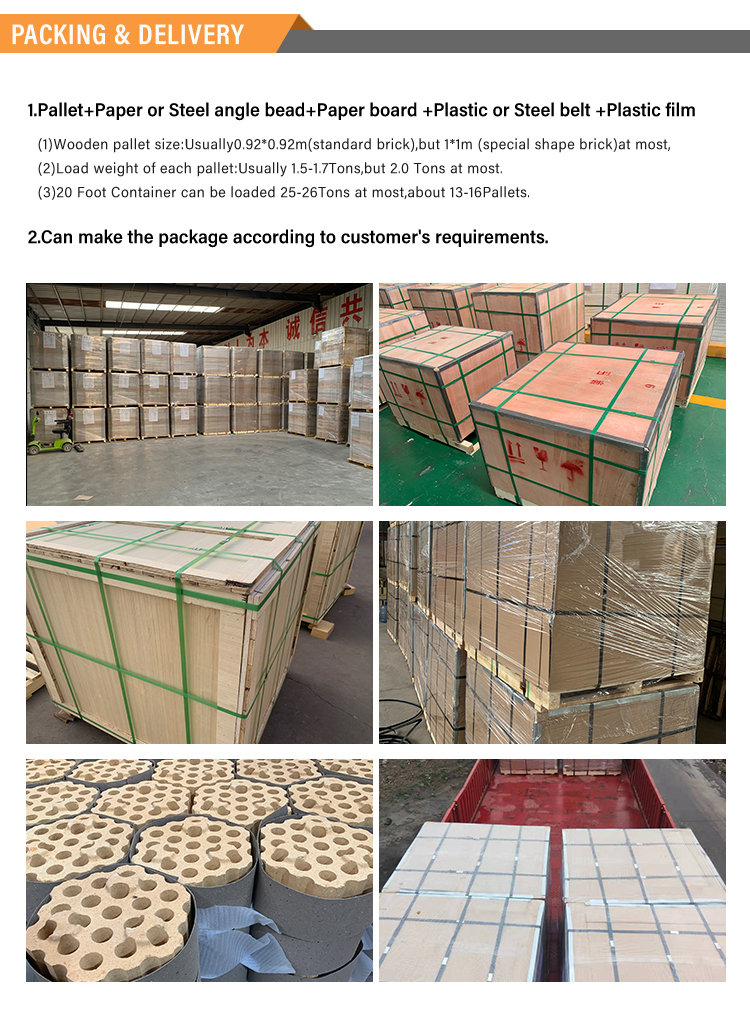

Packing and Shipping of Low-Porosity fire clay brick

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier