Welcome to TradeChina

Factory Direct Sale Hydraulic Hydraulic Jack Tank Lifting Hydraulic Jacks

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Meorient Import & Export Co.LTD

China - Hangzhou

Trading Company

Trade Capacity

Export Percentage

Nearest Port

Hangzhou,Shanghai

Accepted Delivery Terms

Employees

5-10人

Accepted Payment Currency

USD,CNY

Average Lead Time

45 Day(s)

Certifications

Product Specifications

--Product Description

Products Description

Introduction of hydraulic cylinder equipment for storage tank upside-down construction

1 scope of application

This equipment is suitable for storage tank upside-down construction process

2 Equipment composition

This equipment consists of multiple sets of hydraulic jacks, hydraulic stations, power supply parts and control parts. One hydraulic station drives a group of 5 hydraulic jacks. The control part controls the lifting of the hydraulic jack and fine-tunes the start-stop and synchronization of the hydraulic station.

3 Equipment characteristics

This equipment is compact in structure, stable in operation, reliable in operation, adjustable in operation, minimal, fast in installation, and high in synchronization accuracy. The lowest pollution.

The hydraulic jack is single-acting and returns by external force or its own weight. Can be customized for double acting

Equipment composition

●Electrical control system: power distribution box, centralized control operation box (operation console) and pump station control

box.

●Lifting hydraulic cylinders: hydraulic cylinders, steel wire ropes, equator devices, hydraulic cylinder roof devices, hydraulic

cylinder support rods, etc.

box.

●Hydraulic control system: hydraulic jacking pump station, high-pressure ball valve, high-pressure hose and fuel tank, etc.

●Lifting hydraulic cylinders: hydraulic cylinders, steel wire ropes, equator devices, hydraulic cylinder roof devices, hydraulic

cylinder support rods, etc.

★Features

●This set of equipment is mainly composed of hydraulic jacking pump station, hydraulic cylinder, steel wire rope, etc.

It is easy to install.

It is easy to install.

●The equipment adopts PLC program centralized control program, and each group of jacking pumping stations

is equipped with sensors and other devices, which is simple to operate, high in jacking synchronization accuracy, and the jacking

process is stable.

is equipped with sensors and other devices, which is simple to operate, high in jacking synchronization accuracy, and the jacking

process is stable.

●The hydraulic jacking pump station is divided into two modes: manual and centralized control. The hydraulic

cylinder can be adjusted (fine-tuned) up and down individually or locally (several); it can be controlled in multiple groups to

rise and drop; the lifting height can be precise Control, suitable for butt adjustment of tank wall welds.

cylinder can be adjusted (fine-tuned) up and down individually or locally (several); it can be controlled in multiple groups to

rise and drop; the lifting height can be precise Control, suitable for butt adjustment of tank wall welds.

●Each hydraulic

cylinder is equipped with a safety valve, which has good self-locking performance. During the operation of the equipment, there

will be no power outage; a certain high-pressure hose is blasted or broken; the failure of a certain hydraulic cylinder causes the

tank body or heavy objects to block or The hydraulic jacking process is safe and reliable.

cylinder is equipped with a safety valve, which has good self-locking performance. During the operation of the equipment, there

will be no power outage; a certain high-pressure hose is blasted or broken; the failure of a certain hydraulic cylinder causes the

tank body or heavy objects to block or The hydraulic jacking process is safe and reliable.

●Hydraulic cylinders rely on their own

weight and external force to return. Each hydraulic cylinder only uses one high-pressure hose, which avoids the drawbacks of

traditional multiple high-pressure hoses with many oil leakage points.

weight and external force to return. Each hydraulic cylinder only uses one high-pressure hose, which avoids the drawbacks of

traditional multiple high-pressure hoses with many oil leakage points.

●The screw hydraulic jacking device has no lateral force

during the jacking process; it has no effect on the tank wall

during the jacking process; it has no effect on the tank wall

●The stroke of the hydraulic cylinder is 1475mm, which can meet the

one-time lifting of 2500mm wide wall panels, reducing the lifting time.

one-time lifting of 2500mm wide wall panels, reducing the lifting time.

●The overall base length of the equipment is only 2050mm,

which can fully meet the automatic welding process of the inner ring of large storage tanks.

which can fully meet the automatic welding process of the inner ring of large storage tanks.

YT25-2700 type | YT30-3200 type | SYT25-3200C storage tank upside-down construction hydraulic jacking equipment | YT25-2700C (pulley extended range series) |

1. Maximum operating pressure 20 MPa | 1. Maximum operating pressure 24 MPa | 1 Maximum operating pressure 28 MPa | 1. Maximum working pressure 31.5 MPa |

2. Maximum output force of a single hydraulic cylinder 250 kN | 2. Maximum output force of a single hydraulic cylinder 250 kN | 2 Maximum output force of a single hydraulic cylinder 250 kN | 2. Maximum output force of a single hydraulic cylinder 250 kN |

3. The equipment meets the maximum board width ≤2500 mm | 3. The equipment meets the maximum board width ≤3000 mm | 3 The equipment meets the maximum board width of 3050 mm | 3. The equipment meets the maximum board width ≤2500 mm |

4. Maximum stroke of hydraulic cylinder 2700 mm | 4. Maximum stroke of hydraulic cylinder 3200 mm | 4 Hydraulic cylinder maximum stroke 1750 mm | 4. Maximum stroke of hydraulic cylinder 1475 mm |

5. Motor power 4KW 5.5KW | 5. Motor power 4KW 5.5KW | 5 Hydraulic cylinder lifting speed 160 mm/min | 5. Motor power 4KW 5.5KW |

6. Motor speed 1440 r/min 1440 r/min | 6. Motor speed 1440 r/min 1440 r/min | 6 Oil pump flow7.2 L/min | 6. Motor speed 1440 r/min 1440 r/min |

7. Hydraulic cylinder lifting speed 110 mm/min 220 mm/min | 7. Hydraulic cylinder lifting speed 110 mm/min 220 mm/min | 7 Motor speed 1440 r/min | 7. Hydraulic cylinder lifting speed 175 mm/min 350 mm/min |

8. Oil pump flow 7.2 L/min 14.4 L/min | 8. Oil pump flow 7.2 L/min 14.4 L/min | 8 Motor voltage 380V 400 V 415V | 8. Oil pump flow 7.2 L/min 14.4 L/min |

9. Motor voltage ~380V or 415 V | 9. Motor voltage ~380V or 415 V | 9 Motor power 4KW | 9. Motor voltage ~380V or 415 V |

10. Electromagnetic directional valve operating voltage ~220 V | 10. Electromagnetic directional valve operating voltage ~220 V | 10 Use voltage of solenoid directional valve ~220 V | 10. Electromagnetic directional valve operating voltage ~220 V |

11. The equipment meets the working environment temperature -10~60 ℃ | 11. The equipment meets the working environment temperature -10~60 ℃ | 11 The equipment meets the working environment temperature -10~60 ℃ | 11. The equipment meets the working environment temperature -10~60 ℃ |

12. Control method PLC automatic control + manual + local control | 12. Control method PLC automatic control + manual + local control | 12 Control method PLC automatic control + manual + local control | 12. Control method PLC automatic control + manual + local control |

13. Weight of a set of hydraulic jacks (5 cylinders + 1 hydraulic station) 2200Kg | 13. The weight of a set of hydraulic jacks (5 cylinders + 1 hydraulic station) 2700Kg | 13 Weight of a set of hydraulic jacks (5 cylinders + 1 hydraulic station) 3400Kg | 13. Weight of a set of hydraulic jacks (5 cylinders + 1 hydraulic station) 3100Kg |

1.The use environment of the equipment | 2.The overall structure of the equipment | |||||

Ambient air temperature; within the range of -10℃~60℃. | This set of equipment is evenly arranged around the lifted object. The overall force and lateral force of the equipment have been strictly calculated and successfully applied. | |||||

Keep the installation location away from flammable and explosive materials. | ●The structure is rigorous and compact, the output force is adjustable, the lifting speed meets the lifting requirements, and the synchronization accuracy is high. | |||||

PACKING IMAGE

PACKING IMAGE

PACKING IMAGE

The working principle of the equipment | ||||||||

▲Transmission process | ▲Lifting control process | |||||||

●The output force of the hydraulic cylinder → wire rope → expansion ring (welded with lifting lugs) → force transmission rib → wall plate jacking. | ●Pumping station control box (rotating selector button) → centralized control operation box (Figure 1-3) → hydraulic jacking pump station (valve group electromagnet) → equalizing device (equal contact) → centralized control operation box → Hydraulic jacking pump station → hydraulic cylinders are raised and lowered as a whole or partly. | |||||||

●Serial number Parameter name Parameter value 1. Maximum working pressure 31.5 MPa 2. Maximum output force of a single hydraulic cylinder 250 kN 3. The equipment meets the maximum lifting height of 2500 mm 4. Maximum stroke of hydraulic cylinder 1475 mm 5. Hydraulic cylinder lifting speed 160 mm/min 6. Oil pump displacement 5ml/r 7. Oil pump flow rate 7.2 L/min 8. Motor power 4KW 9. Motor speed 1440 r/min 10. Motor voltage ~380 V 11. Electromagnetic directional valve operating voltage ~220 V 12. Control method PLC automatic and manual control 1 | ●Pump station control box (rotating selector button) → control handle → hydraulic cylinder (single or multiple) to fine-tune up and down. ●The equipment is mainly used for inverted construction of vertical coaxial steel storage tanks in petrochemical industry (hydraulic jacking method), and inverted construction of vertical coaxial low-temperature storage tanks. ●The equipment can also be used for vertical lifting and lifting of super large objects. | |||||||

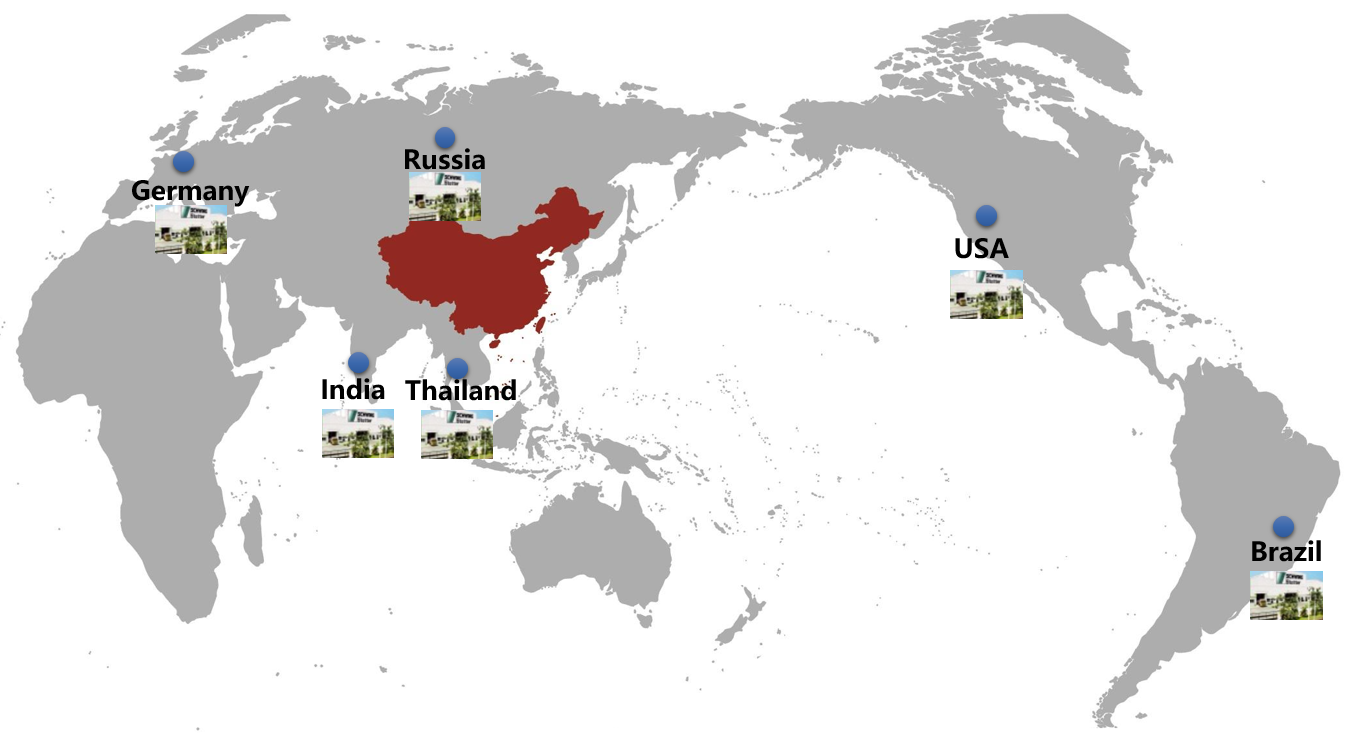

SALES AND SERVICE NETWORK

Successful Project

Project in Dubai

Project in Malasia

Project in USA

SIMILAR PRODUCTS

FAQ

Q1:Can you provide a sample before a big order?

A:Yes, we can .

Q2:Are you able to make Non-standard or customized Hydraulich cylinders?

A:Yes, we can, we have our own factory, we can satisfy the customers' demands

Q3:How long is the warranty?

A:We offer 24 months warranty time.

Q4:Can I have my brand on the products?

A:Of course you can.

Q5:What is your delivery time?

A:3-5days if we have stock, 15-25days if we have no stock.

Q6:How about your quality?

A:Since 1988,and We have 28 more technology patens,We are of the OIL companys is our customer in China,For example :CPNC,SINOPEC,USA ABJ

A:Yes, we can .

Q2:Are you able to make Non-standard or customized Hydraulich cylinders?

A:Yes, we can, we have our own factory, we can satisfy the customers' demands

Q3:How long is the warranty?

A:We offer 24 months warranty time.

Q4:Can I have my brand on the products?

A:Of course you can.

Q5:What is your delivery time?

A:3-5days if we have stock, 15-25days if we have no stock.

Q6:How about your quality?

A:Since 1988,and We have 28 more technology patens,We are of the OIL companys is our customer in China,For example :CPNC,SINOPEC,USA ABJ

we also have confidence to supply good products to our foreign customers.

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier