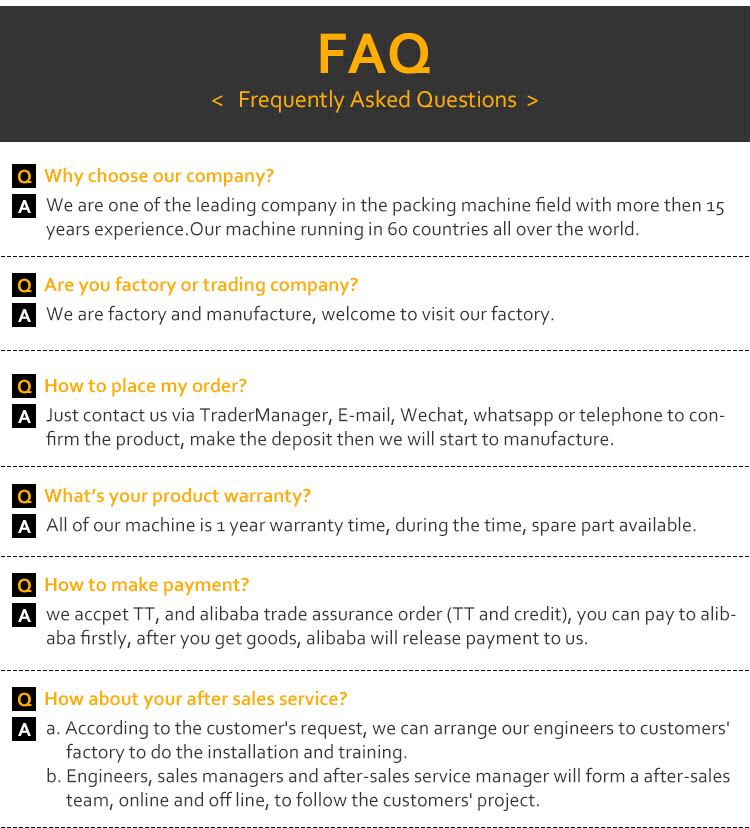

Automatic milk powder and protein powder can production line tin can filling packing machine

Automatic milk powder and protein powder can production line tin can filling packing machine

1. The high-speed automatic canning line includes: can unscrambler → can turning, blowing, sterilization machine → double-head high-precision weighing fillingg machine → vacuum sealing machine → chain conveyor belt → inkjet printer → can turning device → chain Plate conveyor belt → capper → packing platform

2. The supporting machines of this production line are all stainless steel except for the materials indicated, and all machine structures are selected and designed according to food hygiene standards;

3. The whole line equipment is designed according to the GMP standard and fully meets the national food hygiene requirements. Realize the fully automated action of the assembly line to ensure that personnel will not touch the product during the entire production process, and the production process is completely transparent and more reliable.

4. The inner wall of the container in contact with the material is polished, and the structure that is frequently disassembled and washed is connected with easy-disassembled parts to ensure that it is hygienic and convenient to handle when shifting or changing products;

5. The filling accuracy of the system can be controlled within ±1-2g. According to different requirements, the residual oxygen rate after vacuuming and filling with nitrogen can be lower than 3%, which makes your products longer and safer.

6. You can go to the factory for on-site investigation and design the best production plan on the spot; provide free technical support for other aspects of the production line.

Automatic milk powder and protein powder can production line tin can filling packing machine

can feeding machine

Degaussing and purging machine

Degaussing and purging machine

Maximum operating speed: 60 Cans/min

Adapt to the largest tank specification: 502#

Power supply: 3P AC208-415V 50/60Hz;

Whole machine power: 1.65kw;

Dimensions: 1800*540*1173mm;

UV sterilizer

Chain plate width: 152mm

Transmission speed: 10m/min

Power supply: 3P AC208-415V 50/60Hz

Whole machine power: motor 0.55KW, lamp 0.96KW

Machine weight: 200kg

Dimensions: 3200*400*1150mm

Powder weighing filling machine

|

Model |

FCZ-ST |

|

Counting way |

Auger counting filling |

|

Can size |

Φ50-180mm, height 50-350mm |

|

Packing range |

500-5000g (change the inside auger) |

|

Packing error |

±(0.5-2)g |

|

Speed |

8-55/min |

|

Voltage |

380V 3PH or 220V |

|

Power |

2kw |

|

Air pressure/Air consumption |

6--8kg/cm2, 0.2m3/min |

|

Hopper |

50L + 50L |

|

Machine weight |

650kg |

|

Machine size |

3330×1400×2400mm |

auger feeder

Feeding speed: 2-6 cubic meters/hour

Feeding pipe diameter: 114mm

Lifting height: 2.3m (special height can be customized)

Dimensions: length × width × height (2300 × 800 × 2700) mm

Power supply·Power: AC380V·1.2KW

automatic vacuum nitrogen filling and sealing machine

Production capacity: 0-7 cans/minute

Applicable tank diameter: Φ70~Φ130mm

Applicable tank height: 80~190mm

Power supply: 380V 50/60HZ 4.0 kw

Working air pressure (compressed air) ≥0.6MPa

Air consumption (compressed air): about 80L/min

Nitrogen source pressure≥0.4MPa

Nitrogen consumption: about 50L/min

Minimum vacuum pressure -0.09MPa

Machine weight: 600 kg

Dimensions: 2000(L)×800(W)×1850(H)mm

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier