Welcome to TradeChina

Auto feeding system steel structure spraying line steel plate blasting and painting system pretreatment line

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Meorient Import & Export Co.LTD

China - Hangzhou

Trading Company

Trade Capacity

Export Percentage

Nearest Port

Hangzhou,Shanghai

Accepted Delivery Terms

Employees

5-10人

Accepted Payment Currency

USD,CNY

Average Lead Time

45 Day(s)

Certifications

Product Specifications

--Product Description

Auto feeding system steel structure spraying line steel plate blasting and painting system pretreatment line

Product Description

☆Transportation system

Roller conveyor system with frequency control step-less speed regulation.

Painting chamber: Plate chain conveyor with "^" shaped structure, painted steel short-term exposure to avoid film damage.

☆Blast turbine

Power of motor : 7.5-45 kw

Number of turbine: 4-16

☆Intelligent abrasive dosing system:

Service time max 20% longer, energy saved max 30%.

☆Application Industry

Most industries: aerospace, automotive, construction, foundry, shipbuilding, rail, and many others.

☆Workpieces

Sheet steel, profiles, or steel structures, etc.

☆Features

Complete systems quoted

One supplier for all components

Proven technology

Custom designs - Flexible layouts

Simple integration into existing manufacturing processes

Wide range of system sizes and variants

☆Photoelectric detection

Workpiece detection (measure height) adopted world-famous brand photoelectric detection, workpiece width measurement device send a signal to PLC so as to automatically adjust abrasive feeding valve opening number.

☆Abrasive cleaning up

First level: Brush+abrasive reclamation.

Second level: high-pressure blower blow the workpiece twice one after another after blast cleaning.

☆Spray chamber

Adopting GRACO high-pressure Airless spraying pump

Using a standard linear guide trolley, frequency conversion buffer on both ends of trolley stroke. Workpiece detection and transmission system separated from the spray gun set, paint mist interference-free, easy to clean paint scale.

☆Dust collector

Settling chamber + cartridge-type dust collector

Cartridge filter service time: 5 years

☆Delivery time

18-25 weeks

Specification

model | QGPL300 | QGPL500 | QGPL800 | QGPL1000 | QGPL1200 |

Max. workpiece dimension(mm) | 300*600 | 500*1200 | 800*2000 | 1000*2500 | 1200*3000 |

Work speed(m/min) | 0.5-3 | 0.5-3 | 0.5-3 | 0.5-3 | 0.5-3 |

Number of wheels* power(kw) | 4*7.5/11 | 4*7.5/11/15 | 6*7.5/11/15 | 6*11/15 | 8*11/15 |

Wheels optional | 8*7.5/11 | 6*15/18.5 | |||

Dust collector | HR-12 | HR-12 | HR-16 | HR-24 | HR-24 |

Foundation pit required | No | No | No | Yes | Yes |

Company Profie

With 45 years experience of innovating and producing, QINGGONG machinery is a professional manufacturer of wheel blast/air blast machines.

Qinggong machinery have a R&D team with 30 years experience, 50 workers and a factory covering an area of 30,000 ㎡.

Untill 2019, Qinggong machinery have produced 5000+ sets of various kinds of wheel blast, air blast machines for customers from more than 50 different countries and some major factories in China, like LongGong, SANY, TISCO, etc.

TREATING SURFACE, PEENING FUTURE. has been the spirit of Qinggong machinery for decades. With our determined and responsible attitude, we have the confidence of providing the better surface treatment solutions for your industry.

FAQ

Q:How to choose balst machine type?

A:Please tell the information of your work-piece and productivity, experienced engineer will suggest.

Q:How to choose abrasive?

A:Various kinds abrasive with different size: steel shot, cut wire shot, stainless steel shot, etc. Choose according to workpiece.

Q:Quality warranty?

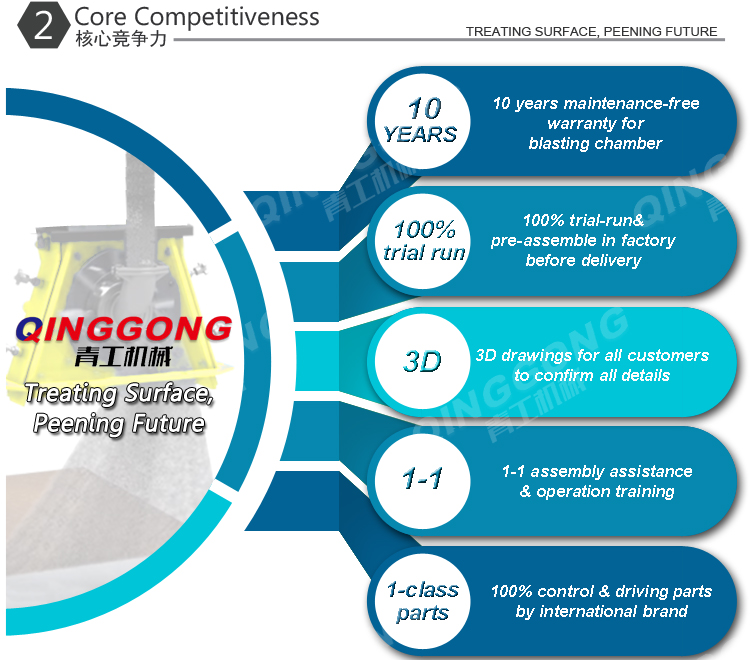

A:1 year for whole machine, 10 years for blasting chamber

Q:Is foundation pit essential?

A:Up to machine size and workshop

Q:How many workers to operate the machine?

A:1-2, up to the machine.

Q:Install assistance?

A:1-1 install assistance & operation training on site by experienced engineer.

Q:After sale service?

A:Full stock for spare parts, regular after sale service.

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier